Mussel culture- A better livelihood opportunity

Backwater mussel culture is a low investment activity opens immense potential for resource and employment generation among coastal communities especially women and youth. It can stimulate a healthy socio-economic development in the area. Better post harvest technologies can develop attractive value added products. Green mussel is widely distributed and found extensively around Kollam, Alapuzha, Kozhikode, Kannur and Kasargod in Kerala and in small beds in Chilka lake, Vissakhapatnam, Kakinada, Chennai, Pondicherry, Caddalore, Mangalore, Karwar, Goa, Ratnagiri and in Gulf of Kutch.

Figure 1: Perna viridis

· Open sea and estuarine areas free from strong waves action may be selected for farming.

· Clear seawater with high plankton production is ideal for mussels.

· Moderate water current will bring the required planktonic food and will carry away the waste materials.

· Silt will adversely affect mussel growth and survival.

· Site selected should be free from industrial pollution.

· Salinity range of 30 - 35 ppt is ideal for mussel farming.

· Water temperature between 21°C to 31°C and dissolved oxygen from 3.8 to 5.5ppm

· In shallow waters in the sea and estuary, rack and ren method can be adopted but for deeper regions in the sea, the raft method will be ideal.

2. Seed collection and seeding of ropes

· Healthy seeds from the submerged (sub tidal) natural beds are to be collected for seeding.

· After removing other organisms and weeds, the seeds may be washed thoroughly in seawater.

Figure 2: spat

Figure 3: Muslin bags

Figure 4: Manual seeding

· Ideal size of seed is 15 -25 mm.

· About 500 to 750 g of seed will be required for seeding on one-meter length of rope.

· The length of rope is decided by considering the depth where the raft/rack is positioned.

· While suspending the seeded rope on rack it must be tied in such a way that the upper portion of the rope should not get exposed during low tide

·

· Nylon rope of 12-14 mm or 15-20 mm coir rope can be used for seeding.

· Old cotton net, cotton mosquito net or cheap cotton cloth etc. is used for covering the seeds around the rope.

· After placing the rope over the seed, the net is tightly stitched in such a way that the seeds spread uniformly around the rope.

· Cotton net around the seed will disintegrate in a week time.

· The seed will secrete byssus threads and will attach itself to the rope within this period.

Rack, Raft and Longline culture

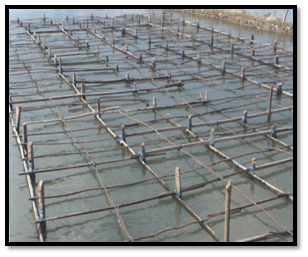

Raft culture is the most popular method in which seeded ropes are suspended from a raft set in a desirable site and depth in the inshore area. The ropes are set 0.5 to 1m apart and care is taken to ensure that the end of the rope is about 2m above the water bottom. Raft culture is more suited to areas of dense phytoplankton and to smaller operations, as there is less scope for mechanical harvesting. This is the simplest of the rope-web method used for green mussel cultivation in India and Philippines. The main purpose of the pole is to support the structure. In between these poles, ropes are suspended either vertically or kept horizontally where the depth is a limitation. Rack culture mussels are suspended on droppers but these are suspended from the raft instead of the long lines. The raft itself is anchored to the seabed removing the need for several anchoring systems. Long line culture however, creates less of a visual impact, and the droppers can be spaced farther apart to maximize the use of the available phytoplankton.

Raft culture

Rack culture

Longline culture

Figure 4: Mussel culture areas in Goa

To maintain the quality of bivalve products depuration is essential. Simple depuration can be achieved by starving the bivalves in clean and filtered seawater/ brackishwater for a certain period of time. More effective depuration can be achieved by using disinfected water in the depuration process.

A number of different products from mussel meat have been developed over the years. Central Institute of Fisheries Technology has been successful in the development of dried and smoked mussel meat, marinated mussel meat, mussel meat pickle, mussel meat chutney powder, canned mussel meat, ready-to-serve fried mussel meat, condiment incorporated, ready-to-eat, fried mussel meat in vacuum packaging etc. However, it is seen that very few mussel products are readily available to the consumer at the retail market. The mussel shells are composed of calcium carbonate. The shells can be commercially exploited to make lime.